Wood is a living material that follows natures laws, and it requires both experience and professional skill to distinguish a properly manufactured parquet floor from one that does not meet our high-quality standards. Even small differences in quality can significantly impact how a solid wood floor maintains its function and beauty over many decades. Here are some important aspects we consider when making high-quality solid wood floors.

Properties of different wood species for flooring

To ensure the finished floor meets specified requirements, it is important to consider the properties of different wood species. Oak, ash, cherry, and maple are examples of durable wood species suitable for environments with heavy wear. Birch, on the other hand, is softer and should be used in areas that do not experience as much traffic. Beech is slightly softer than oak but is still considered durable. However, beech is more sensitive to climate changes and tends to shift more frequently between winter and summer, making it critical to maintain the correct moisture content.

There are also manufacturers working with parquet made from exotic wood types. These can offer not only beautiful appearances but also extreme hardness. However, it is worth noting that there is no need for more durable wood types than oak and ash, which already provide excellent resistance to wear over a long time.

Eight Important Characteristics of a Genuine BURSERYD Parquet Floor

1. Moisture Content/Drying

For the parquet to withstand climate changes between dry winters and humid summers, the parquet must be dried to a specific moisture percentage. In Sweden, this percentage should be 7% (±2%). If the moisture is higher, the parquet will shrink, and if lower, the material expands.

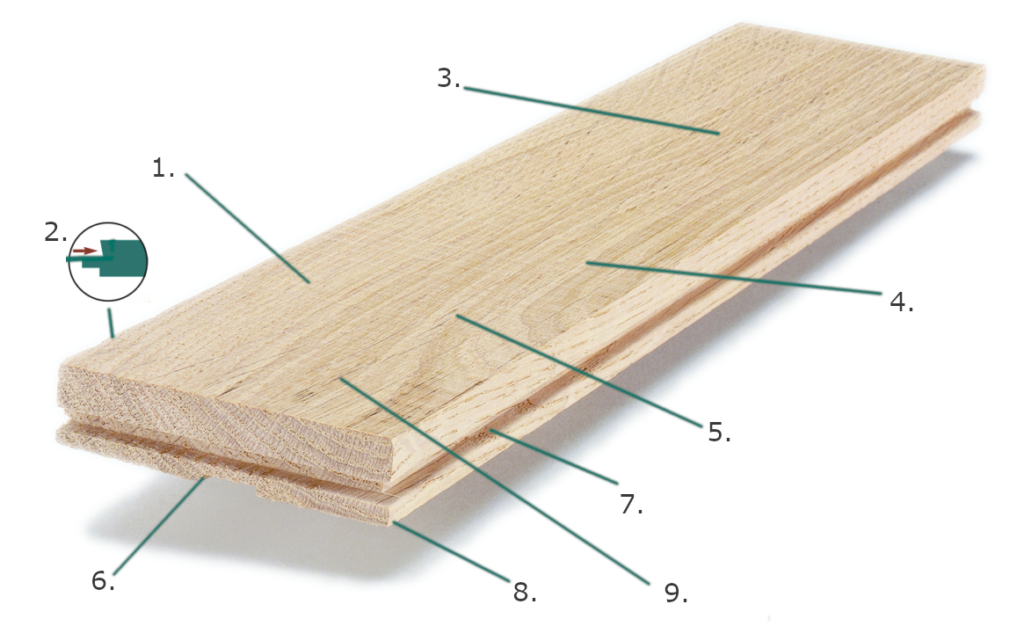

2. Profile

The strip should be slightly chamfered to ensure tightness between the strips.

3. Straightness

A special manufacturing technique is required to guarantee the straightness of the strip. A straight strip is a basic prerequisite for a satisfactory result.

4. Raw Material

Without full control over the wood raw material, there is a risk of uneven quality. Therefore, the raw material should come from a limited number of known suppliers.

6. Warping

The parquet strip must have correct milling on the underside to eliminate the risk of cupping.

5. Tolerances

High precision in manufacturing is important to keep the tolerances on the strip as minimal as possible in terms of squareness, length, width, and thickness. A strip that does not maintain sufficiently low tolerance values is virtually impossible to lay in patterns.

7. Tongue/Groove

The fit of the tongue and groove is very important. Partly to avoid floor squeak but also to ensure an even surface. The tolerance for the Burseryd strip is about 0.1 mm between the tongue and groove.

8. Packaging

A strong, airtight packaging is required to ensure maintained moisture content and to protect the strip. We use strong shrink wrap.

9. Grading

Many grading criteria do not become properly visible until after surface treatment, requiring great skill and experience.